MicroGISTrack special machinery monitoring

GPS/GLONASS monitoring system for special machinery is a simple and effective tool for reducing the current costs of maintaining and maintaining a fleet of special machinery.

GPS/GLONASS monitoring system for special machinery - provides effective control and management of the transport complex of a city or a fleet of special machinery of an enterprise due to logistics automation technologies, satellite tracking, GPS monitoring and much more.

The use of GPS / GLONASS systems for monitoring and controlling special machinery is a qualitatively new level of fleet management.

Special machineryis the leader in terms of payback time for GPS/GLONASS monitoring systems.

Features of the GPS/GLONASS monitoring system for special machinery:

- The use of this system is possible on any modern technology, without causing harm to regular electronic systems.

- The system is completely autonomous and does not require intervention in the work of regular systems of special machinery.

GPS/GLONASS monitoring system for special machinery provides:

- Monitoring the location and condition of special machinery without leaving your home or office;

- Monitoring compliance with the operating modes of special machinery;

- Safety of your special machinery;

- Prevention of misuse of special machinery;

- Improving the efficiency of using special machinery;

- Improve the efficiency of job scheduling;

- Prevention of fuel theft;

- Reduction of costs and prices for the repair of special machinery;

- Identification of dishonest employees;

- Statistics and analysis of the activity of the park;

What does the customer need to have?

- Any personal computer or mobile device with Internet access;

- Satellite terminal (tracker) installed on special machinery;

What are the advantages of the GPS/GLONASS monitoring system for special machinery?

- The customer can control moving objects in real time.

- The system does not require the preparation of a special workplace for control.

- The system does not require the installation of special software for monitoring.

- Access to the database of objects is carried out from any computer or mobile device that has Internet access through a regular WEB browser.

- No special knowledge or training is required to use the system.

- The system keeps a history of movements over a long period of time.

- The system works with a large number of open map services.

How does it work?

- The satellite terminal is discreetly installed inside special machinery and connected to systems whose parameters need to be controlled by the customer;

- Control over the movement of machinery, as well as controlled parameters, is carried out using the Internet in real time;

- In the event of an emergency situation, the driver will be able to send you or the operator an alarm signal with one click on the “panic” button;

- A huge number of reports available in the system will greatly simplify the analysis of the performance of both individual machinery and the fleet as a whole;

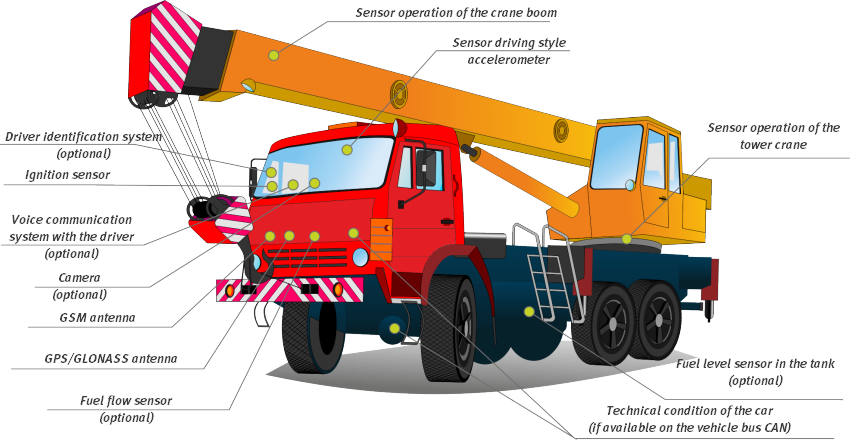

- Satellite terminals installed on special machinery, at the request of the customer, can be additionally equipped with cameras, speakerphone kits, immobilizers, information boards, fuel consumption sensors ...

Scheme of operation of the GPS/GLONASS monitoring system for special machinery:

The system implements:

- Remote control over the movement of special machinery;

- Remote control of modes and parameters of operation of special machinery / mechanisms;

- Remote check of the status of special machinery systems (including the battery);

- Remote control of gas stations and fuel consumption;

- Remote control of the route sheet of the task;

- Additional types of control: photo control, geo-zone visit control, access control;

- Remote blocking of the engine operation / Control of the operation of mechanisms;

- Transmission of alarm signals from the SOS button (panic button) to the system manager with full duplication to the owner's phone numbers;

Additional features:

- Building geofences with the ability to control entry/exit from/to the zone(s);

- Construction of geocorridors with the ability to control entry/exit from/to the corridor(s);

- Building/planning routes and calculating their distances;

- Building route sheets and tasks;

- Building a large number of reports on the work / use of special machinery;

- Building a large number of reports on the work of drivers;

Types of reports:

- Report on the operation of units and mechanisms;

- The distance traveled for the period;

- The distance traveled during the work;

- Travel time per period;

- Downtime per period;

- Report on movement in geofences;

- Report on visiting geofences;

- Report on movement in geocorridors;

- Report on visits to geocorridors;

- Fuel consumption reports;

- Report on fuel consumption according to norms (coefficients are available);

- OBD diagnostic report;

- Speeding report;

- Report on exceeding the set speed;

- Report on the last location of monitoring objects;

- HR information report;

- Report on excessive inactivity of monitoring objects;

- Trip history report;

- Reports on the work of drivers;

- Photo reports;

- As well as group and summary reports.

Effect of implementing a GPS/GLONASS monitoring system for special machinery:

- Significant fuel economy;

- High-quality logistics and optimization of routes / tasks;

- Control of the speed limit and time on the route;

- Constant and reliable control of the location of special machinery;

- Constant and reliable control over the operation of mechanisms;

- Efficiency in the use of special machinery;

- Reduction of cases of exceeding the established standards (violation of the speed limit, deviation from the given route, etc.);

- Real-time monitoring and control of routes

- Exclusion of misuse of technology;

- Discipline of drivers and dispatchers;

- Stability in the provision of services;

- Customer satisfaction;

- Reducing fuel costs and related costs;

- Reducing the cost of maintenance of special machinery;

- Reducing the cost of mobile communications;

- Increasing the service life of special machinery;

- Always access to rich insights and reports

Conclusion:

- The amount of investment in machinery, operating costs and payback period have reached a level acceptable even for small organizations and private entrepreneurs.

- Modern, reliable machinery offered by our company is the safety of your special machinery in modern conditions.

- Therefore, it's time to think about whether to remain in the dark and work according to the old scheme, or switch to new advanced technologies that allow you to be more confident in your own safety?!